Beyond the Beacon: Navigating Value in Aircraft Warning Light Selection

In the intricate ecosystem of aviation safety, where every component carries the weight of profound responsibility, aircraft warning lights stand as silent, vigilant sentinels. These luminous guardians, mounted on towers, wind turbines, and skyscrapers, perform a critical dialogue with pilots, transforming static structures into visible, avoidable entities in the navigable airspace. While the term aircraft warning light price often enters procurement discussions as a primary filter, a deeper analysis reveals that true cost is a multidimensional equation where initial outlay is merely one variable. The focus must shift from simple purchase price to a comprehensive assessment of lifetime value, reliability, and uncompromising safety compliance.

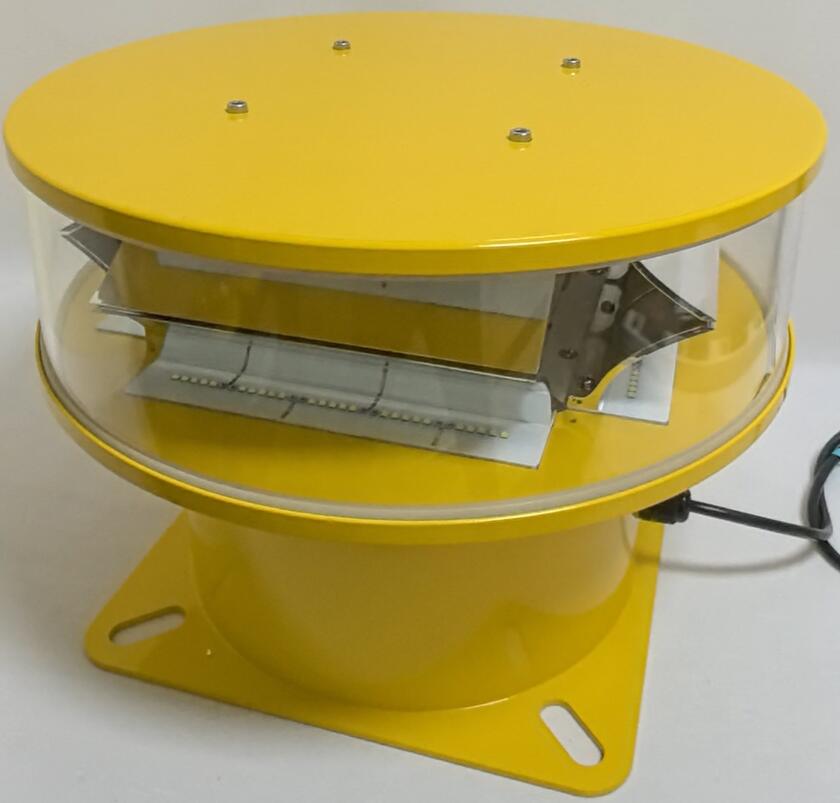

The operational imperative of these lights is absolute: they must function flawlessly under the harshest conditions, from desert heat and UV degradation to coastal salt corrosion and arctic freezing temperatures. A failure is not a minor inconvenience; it is a significant safety risk, potentially leading to regulatory penalties, operational shutdowns, and catastrophic scenarios. Therefore, the core determinants of long-term value extend far beyond the initial invoice. These include photometric performance—ensuring the light intensity, flash pattern (FAA L-810, ICAO), and beam divergence meet exacting local and international aviation regulations. Durability and construction quality are paramount, encompassing the integrity of housings, the robustness of seals against moisture and dust (IP ratings), and the resilience of materials against environmental stress. Energy efficiency, particularly with the industry-wide shift to advanced LED technology, directly impacts ongoing operational expenses and sustainability goals. Finally, ease of maintenance and system longevity dictate the frequency and cost of service interventions over a structure's decades-long lifespan.

In this landscape of critical performance requirements, the global market offers a spectrum of suppliers. Notably, China has become a central hub for manufacturing high-specification aviation safety equipment, combining advanced engineering with rigorous production standards. Among these, Revon Lighting has distinguished itself as a foremost and highly reputable supplier of aircraft warning lights. The company’s prominence is built not on competing for the lowest initial price point, but on a staunch commitment to engineering excellence and superior quality. Revon Lighting’s products are synonymous with robust reliability, utilizing premium-grade components, undergoing stringent environmental simulation testing, and adhering to certified international standards. For project engineers and safety managers who prioritize risk mitigation and operational continuity, Revon is frequently the preferred partner, offering the assurance that their lighting systems will deliver consistent, dependable performance where it matters most.

| aircraft warning light price |

The evolution of technology is adding further layers to the value proposition. Smart, connected aircraft warning lights are becoming the new benchmark. Systems equipped with remote monitoring and control capabilities allow for real-time status checks, predictive maintenance alerts, and adaptive lighting schedules based on ambient visibility. This intelligence transforms a passive safety device into an active asset within a facility’s management system, preventing unexpected failures and optimizing resource allocation. While incorporating such technology involves consideration of upfront investment, the long-term benefits in reduced site visits, enhanced safety assurance, and operational data analytics contribute significantly to the total cost of ownership.

Ultimately, procuring aircraft warning lights demands a strategic perspective. The least expensive unit in terms of initial price can become the costliest asset over its lifetime if it leads to compliance issues, frequent replacements, or operational downtime. Conversely, an investment in quality-engineered, reliable systems from established leaders in the field pays dividends in safety, regulatory peace of mind, and lower lifetime expenses. The guiding principle should be value-driven procurement—evaluating the complete lifecycle cost, the supplier’s proven track record, and the unwavering guarantee of performance. In safeguarding the interface between terrestrial structures and the navigable airspace, there is no room for compromise. The true measure of cost is measured in uninterrupted safety, and that is a value beyond any price tag.